- #Open loop plant simulation how to#

- #Open loop plant simulation drivers#

- #Open loop plant simulation code#

#Open loop plant simulation how to#

In this section, we describe step by step how to run the firmware on the power board.

dsPIC33CK256MP506 Digital Power PIM, Part-No. Four-Switch Buck-Boost Development Board, Part-No. Please always check for the latest data sheets on the respective product websites: dsPIC33CK256MP508 Family Silicon Errata and Data Sheet Clarification. Four-Switch Buck-Boost Development Board. The related documentation can be found on the appropriate product website #Open loop plant simulation drivers#

In our example code, the scheduler executes drivers for the Human Machine Interface (HMI) and for communication with the Board Power Visualizer GUI. The firmware also includes a scheduler to allow the user to easily add their own housekeeping functions. It can run without external cooling up to 20W and 2A at the output. The input voltage range is 8V to 18V, and the output voltage range is 5V to 20V. The associated firmware uses average current mode control to regulate the output voltage. The pin-out is compatible for EP, CK and CH dsPIC® DSC DP PIMs. A mating socket for dsPIC33 Plug-In Modules allows the system to be evaluated with different controllers. For example, input power can be a standard 12V vehicle power rail and operate within the automotive ambient temperature range. TheĮlectrical characteristics are applicable to automotive requirements and can be used for these applications as well. Plug-In Modules (DP-PIMs), Human Machine Interface (HMI) and test points. The board provides organized building blocks that include an input filter, power stage, AUX supply, mating socket for Microchip’s newest Digital Power

#Open loop plant simulation code#

This power board is a generic development board for this topology that supports rapid prototyping and code development based on dsPIC33 devices. This solution demonstrates the implementation of a 4-switch buck-boost converter using average current mode control on the Four-Switch Buck-Boost Development Board (4SWBB). We recommend that the user's guide is studied before reading this document. This document is intended as a supplement to the user's guide.

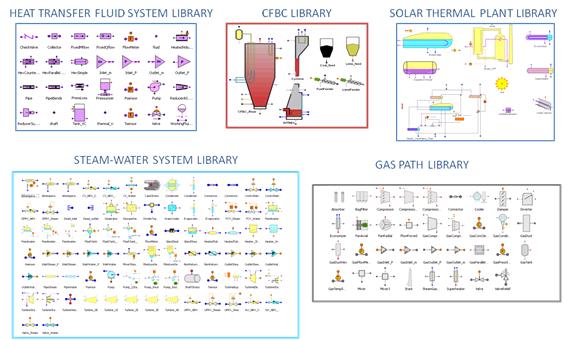

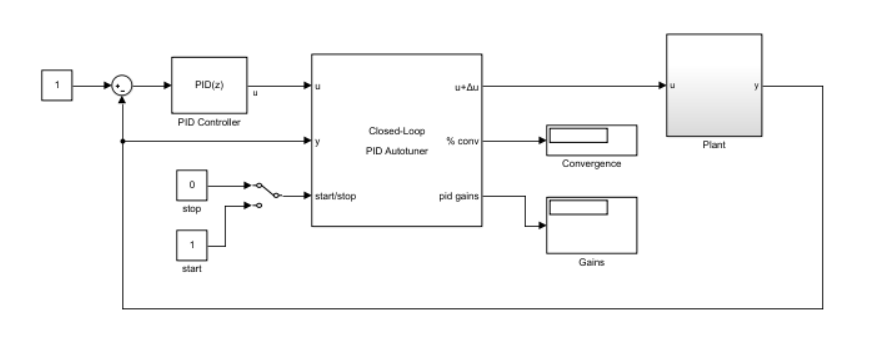

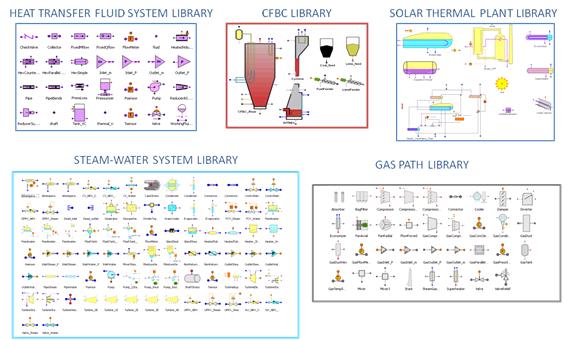

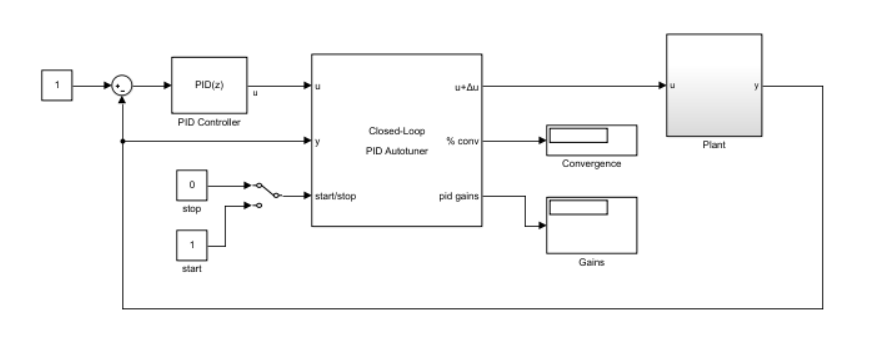

Importing Plant Frequency Response into DCDT. A note on DC gain of the Plant Measurement with Mindi. Plant Frequency Response Simulation with MPLAB® Mindi™. Running Closed Loop with a Fixed Reference. Running Closed Loop with Poti Reference. Setting up and connecting the board power visualizer. The performance of these predictive controllers is compared in simulation against existing classical control techniques in a number of typical operating scenarios including off loads, on loads and set point changes.DsPIC33 Four Switch Buck-Boost Converter 4-Switch Buck-Boost Converter: Average Current Mode Control The predictive controllers we designed include physical constraints on the fuel and air flow into the turbine. These open-loop models are then used in the design of model predictive controllers at a number of operating points of the turbine. The closed-loop data can be obtained by any sufficiently informative experiment from a plant in operation or simulation. In this paper, a methodology is introduced to identify linear open-loop models of gas turbine engines from closed-loop data. Despite these advantages, obtaining an accurate open-loop model of the underlying process is often a difficult and time consuming process. The anticipative nature of MPC and the inclusion of physical constraints into the control framework presents many advantages over classical control strategies. The use of Model Predictive Control (MPC) is commonplace in many industrial applications. Journal of Verification, Validation and Uncertainty Quantification. Journal of Thermal Science and Engineering Applications. Journal of Offshore Mechanics and Arctic Engineering. Journal of Nuclear Engineering and Radiation Science. Journal of Nondestructive Evaluation, Diagnostics and Prognostics of Engineering Systems. Journal of Nanotechnology in Engineering and Medicine. Journal of Micro and Nano-Manufacturing. Journal of Manufacturing Science and Engineering. Journal of Engineering Materials and Technology. Journal of Engineering for Sustainable Buildings and Cities.  Journal of Engineering for Gas Turbines and Power. Journal of Engineering and Science in Medical Diagnostics and Therapy. Journal of Electrochemical Energy Conversion and Storage.

Journal of Engineering for Gas Turbines and Power. Journal of Engineering and Science in Medical Diagnostics and Therapy. Journal of Electrochemical Energy Conversion and Storage.

Journal of Dynamic Systems, Measurement, and Control. Journal of Computing and Information Science in Engineering. Journal of Computational and Nonlinear Dynamics. Journal of Autonomous Vehicles and Systems. ASME Letters in Dynamic Systems and Control. ASCE-ASME Journal of Risk and Uncertainty in Engineering Systems, Part B: Mechanical Engineering. Mechanical Engineering Magazine Select Articles.

0 kommentar(er)

0 kommentar(er)